Hot Air Generator Manufacturer

Product Introduction & Application:

Biggest challenge the industry faces is the productivity and production cost which is directly linked to consumption of fuel for heating applications. Industrial Fabricators make HAG are specifically designed to meet the challenges of low fuel consumption without compromising the process requirements. Air Heating is one of a most basic requirements in majority of the industry. Most of the industrial processes are carried out by indirect or direct heat treatment.

Design characteristics

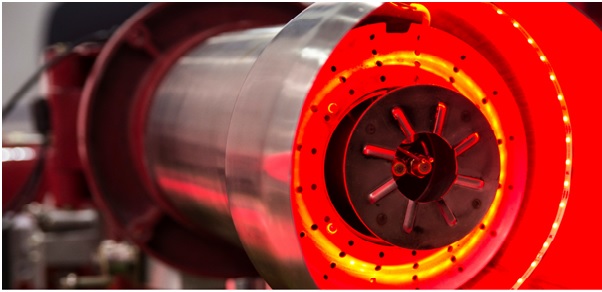

As the name suggests, A hot air generator manufacturer is an equipment which produces air, which is channelized and passed through a heating media with the help of a centrifugal blower (Induced draft or forced draft). The air which is heated now is delivered to the application area via insulated ducts. Depending up on temperature requirements, number of passes, MoC etc. are determined and finally passed for manufacturing.

HAG’s are of two main types, Direct & Indirect. The direct system is one in which the hot air passes directly through the heating media. The indirect system is the one where the air do not come in direct contact of the heating media.

Fabricated out of heavy-duty sheets/plates to withstand the extreme temperatures, the system is not just robust but gives an attractive design. Mounted on a sturdy mono-block type structure which enables the system to work effectively in most adverse conditions.

Comes with a wide verity of options for heating media like Wood, Coal, Electric, Steam, Thermic Fluid, Hot water, Hot Oil (Thermic Fluid) Gas, Heat Pump etc. It also includes some of the advanced technology to operate on Renewable energy and cleanest energy sources like Solar Thermal, Solar air collection, Geothermal etc. and comes with an option of hybrid systems where a combination of heating media both Renewable and Natural resources.